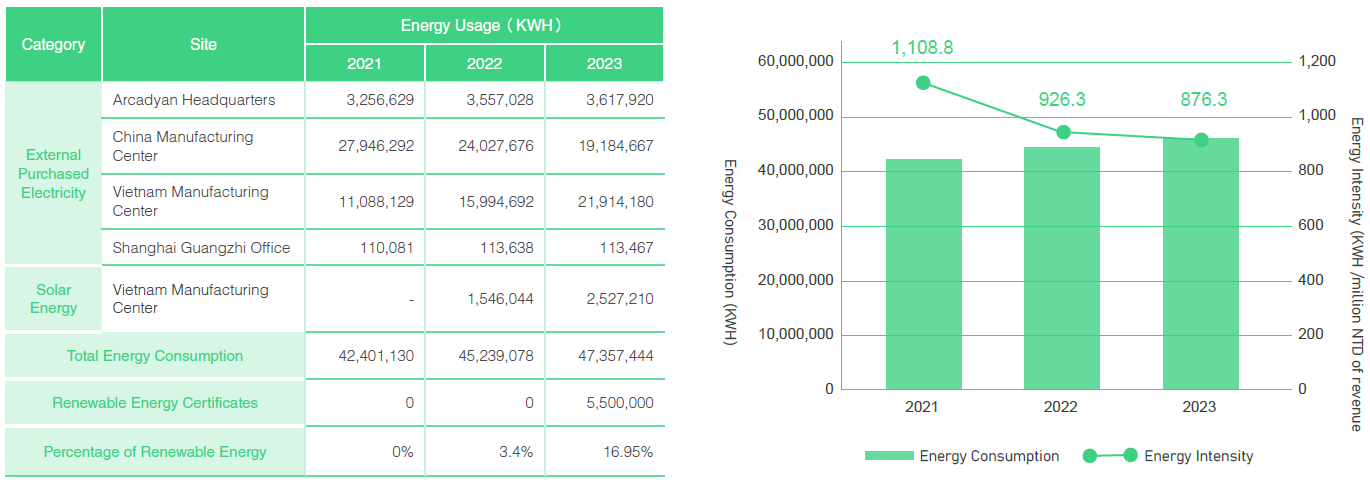

Arcadyan's headquarters and overseas manufacturing centers primarily rely on purchased electricity to achieve the net-zero emissions goal, emphasizing energy management at plant sites. Arcadyan scrutinizes electricity usage behaviors at these facilities, identifies energy-saving opportunities, implements demand-side management, and establishes energy monitoring systems to achieve benefits in energy conservation, cost reduction, and carbon emission reduction. In 2023, Arcadyan achieved a energy intensity of 876.3 (KWH/million NTD revenue), marking a decrease of 5.4% compared with the energy intensity of 926.3 (KWH/million NTD revenue) in 2022, which is better than the energy intensity set for 2022, which is reduced by 1 %Target.

-

Arcadyan Headquarters Smart Energy Management Project

In 2023, Arcadyan's Hsinchu headquarters collaborated with external energy technology service providers to implement an energy management project. The project targeted identified energy hotspots, such as high-energy-consuming equipment like chiller units and cooling towers in the air conditioning systems. It involved conducting a structural analysis of energy use and introducing an automated monitoring system to enhance transparency and visualization of energy consumption. Furthermore, variable frequency drives (VFDs) and temperature monitoring interfaces were installed on the air conditioning units. These interfaces transmit real-time temperature data to the control system, allowing the system to automatically adjust motor VFD settings based on temperature feedback. This improves response times and system efficiency, reducing energy waste and ensuring stable indoor temperatures. The installation of VFDs and temperature monitoring interfaces also extends equipment lifespan and reduces maintenance costs. Arcadyan remains committed to achieving sustainable development goals through innovative technologies and effective power management practices.

-

Vietnam Manufacturing Center Establishes Energy Monitoring Center

In 2023, Arcadyan Vietnam Manufacturing Center established an Energy Monitoring Center (EMC). This facility operates around the clock with a centralized system for real-time energy monitoring, consumption analysis, alert notifications, and energy usage diagnostics. The EMC ensures transparency in electricity consumption and effective implementation of energy-saving strategies. This initiative not only detects energy anomalies promptly but also optimizes energy efficiency measures, potentially saving approximately 360 MWh of electricity and reducing around 260 tons of carbon emissions annually. Beyond financial savings, these efforts significantly contribute to environmental sustainability, aligning with Arcadyan's commitment to green manufacturing practices.