Since 2005, Arcadyan has implemented the ISO 45001 Occupational Health and Safety Management System, establishing environmental health and safety policies and safety management procedures at each plant to control every workplace detail. The design of both software and hardware facilities in the office environment prioritizes employee safety. All entrances are equipped with access control card readers, restrooms have emergency push buttons, and each floor is equipped with AEDs (automated external defibrillators). Security personnel guard the main entrances 24/7 to ensure employee safety. All electrical, mechanical, and fire safety equipment (such as fire alarms and extinguishers) are maintained or repaired regularly as per specified schedules to ensure they remain in optimal working condition.

ISO 45001 Occupational Health and Safety Management System Policy

- Comply with the domestic environmental, health / safety, and energy regulations, and effectively implement the environmental, health / safety, and energy management system.

- Promote training and publicity on environmental, safety and health, energy and product eco-design.

- Implement comprehensive employee health management, proactively prevent occupational accidents, and create a zero-incident safe workplace.

-

Occupational Hazard Identi cation and Risk Assessment

Arcadyan adheres to the ISO 45001 Occupational Health and Safety Management System by establishing the "Procedures for Environmental Considerations and Hazard Identification Risk Assessment Management." Through the "Safety and Health Hazard Identification and Risk Assessment Form," hazards are identified and risk levels are classified, allowing the company to formulate response policies and control measures.

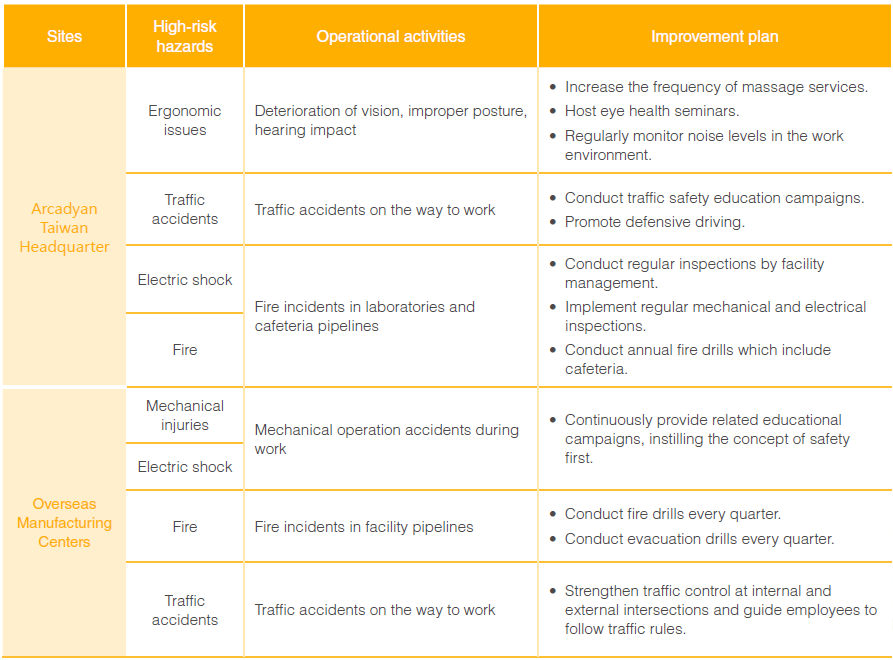

In 2023, Arcadyan Taiwan Headquarter identified four high-risk hazards: ergonomic issues, traffic accidents, electric shock, and fire. Similarly, the overseas manufacturing centers identified four high-risk hazards: mechanical injuries, electric shock, fire, and traffic accidents. These high-risk hazards have been included in management programs for improvement, while other risks are controlled through documentation and routine inspections.

-

Occupational Safety Education and Training

Arcadyan has established "Procedures Emergency Preparedness and Response" to assist employees in understanding disaster levels, evacuation routes, and other related matters within the plant area. The company conducts regular disaster prevention knowledge dissemination annually, including correct procedures for handling fires, storms, floods, earthquakes, etc. Arcadyan also coordinates with local fire departments to conduct fire drills according to their instructions.

At Arcadyan Taiwan Headquarter, environmental health and safety system introductions and electrostatic protection training are included in the new employee orientations. In 2023, a total of 1 session was held with 78 participants. Additionally, a biannual fire education training and fire drill is conducted, integrating theoretical knowledge with practical exercises. Overseas manufacturing centers comply with local regulations in conducting fire drills. In 2023, CNC China Manufacturing Center conducted 3 sessions, involving a total of 4,500 participants in safety and health education training and evacuation drills. AVC Vietnam Manufacturing Center conducted 2 fire drills, involving a total of 4,128 participants in fire evacuation drills. Furthermore, occupational safety and health series courses covering various safety management, chemical use, radiation safety, and first aid training were conducted, totaling 3,240 participants completing the training.

-

Occupational Injuries

Arcadyan adheres to the definitions of occupational injuries as per the Occupational Safety and Health Act and the key disability injury statistics provided by the Global Reporting Initiative (GRI). Annually, Arcadyan records the disabling injury frequency rate (FR) and severity rate (SR) to monitor employee work safety. In 2023, there were no occupational injury incidents at any of Arcadyan's global operation sites. Additionally, Arcadyan Taiwan Headquarter has participated in the "Occupational Accident Free Record," accumulating 17,684,770 hours without any accidents from 2008 to the end of 2023. Arcadyan is awarded with the Golden Award in Occupational Accident Free Record by the Industrial Safety and Health Association of the R.O.C. in 2023.

(News: Arcadyan received Golden Award for Occupational Accident Free Record)

Health Care and Promotion

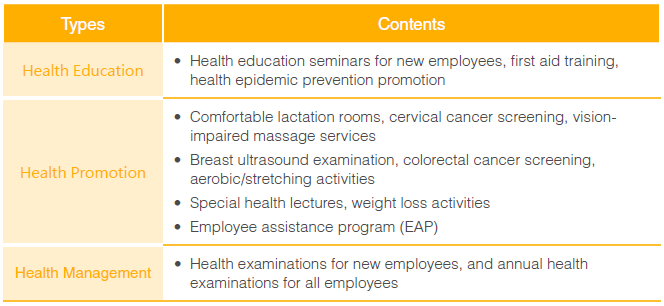

Employees are Arcadyan's most valuable asset, and their health is crucial for the company's success and sustainable development. Providing a healthy and comfortable working environment for all employees is Arcadyan's goal. Arcadyan has established a health center staffed with professional nursing personnel, on-site physicians, and contracted medical institutions. It focuses on three main directions: health education, health promotion, and health management, ensuring the well-being of each employee.

-

Female Employee Care

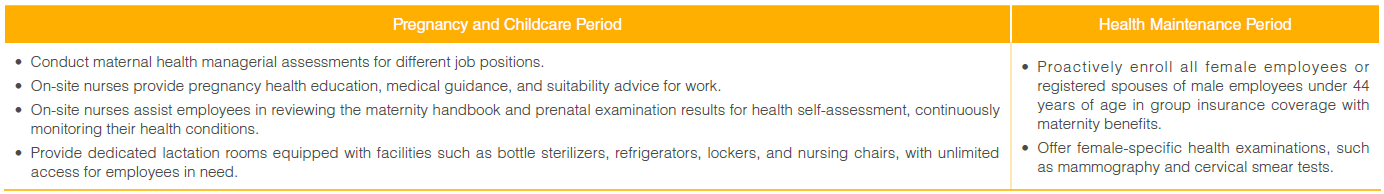

Arcadyan Taiwan Headquarter, CNC China Manufacturing Center, and AVC Vietnam Manufacturing Center together employ over 2,500 female employees. The company provides comprehensive care for female colleagues, ensuring their diverse needs during pregnancy are met.

Arcadyan attaches great importance to the development of gender equality, provides diversified care for female employees, and meets the needs of female employees during pregnancy. To promote and support the fertility rate of female employees, Arcadyan not only provides maternity bonuses, but also provides a friendly, safe and comfortable nursing environment, allowing female employees to strike a balance between childcare, family and work, and increasing the female workplace participation rate. Arcadyan was awarded the Excellent friendly nursing room company by the Hsinchu City Government on August 7, 2024.

-

Employee Assistance Program (EAP)

Arcadyan understands that employee well-being is crucial for optimal job performance. In order to effectively assist employees in addressing issues that may affect their work, such as mental health, interpersonal relationships, emotional stress, marriage and family matters, financial concerns, legal issues, etc., Arcadyan is introducing an Employee Assistance Program (EAP) in 2024. In 2023, Arcadyan conducted information sessions to help employees familiarize themselves early with the usage and scope of services offered by the EAP, ensuring that the program can deliver maximum effectiveness upon its launch.