Energy Use

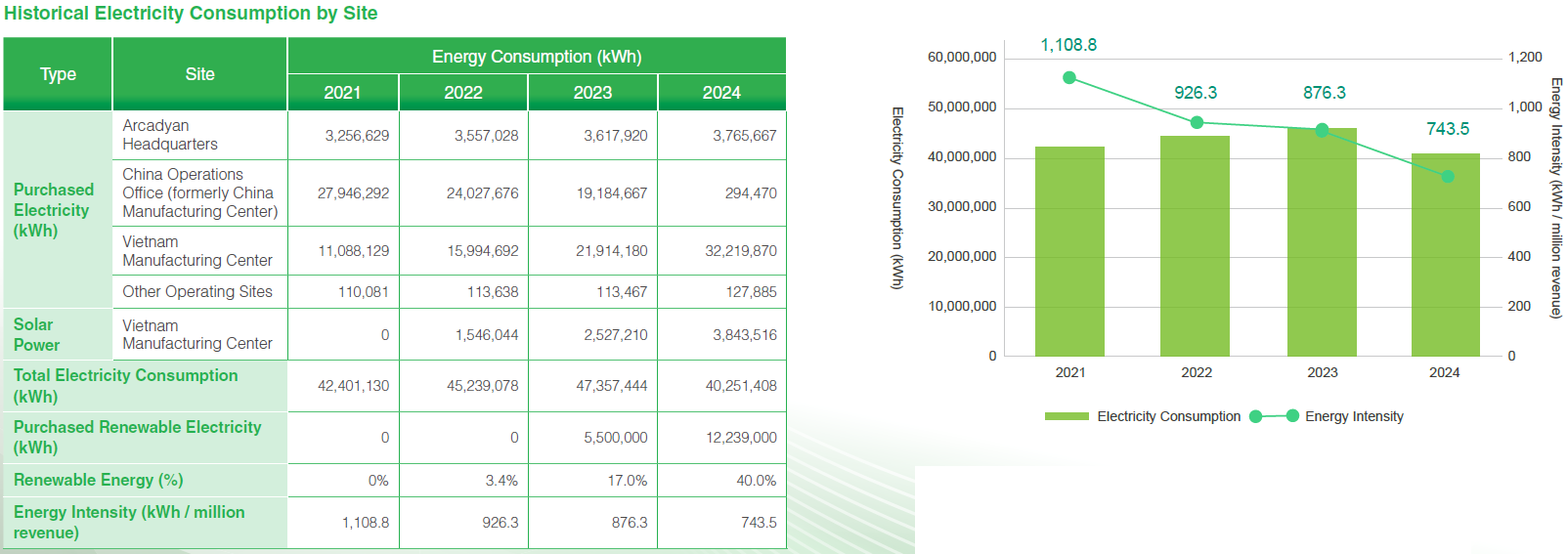

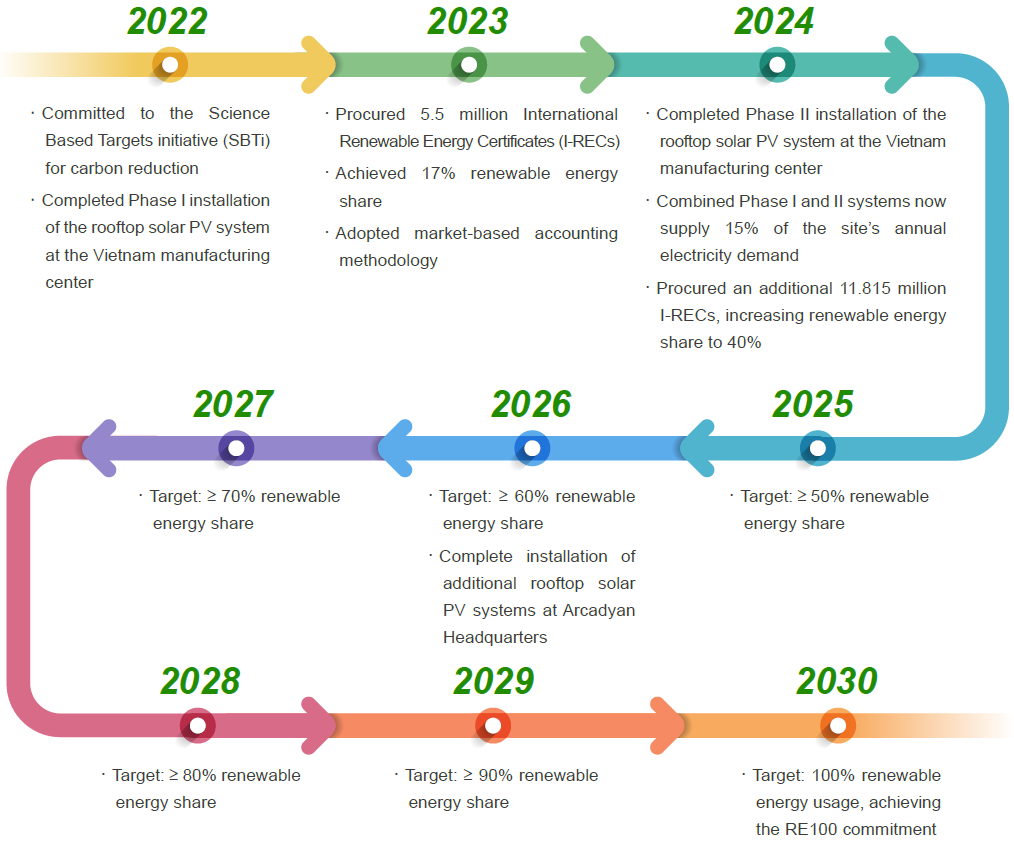

The primary energy consumption at Arcadyan's operational sites comes from purchased electricity. To support the Group's net-zero emissions target, strengthening energy management has become a top priority in its decarbonization strategy. In order to systemically monitor and optimize energy use, Arcadyan has fully implemented the ISO 50001 Energy Management System across its headquarters and manufacturing center. Through standardized processes and real-time energy monitoring mechanisms, the company conducts in-depth analysis of energy hotspots within its facilities. Based on the analysis results, targeted strategies for electricity management and demand control are executed to enhance energy efficiency and achieve the combined benefits of energy conservation, cost reduction, and carbon emission reduction. In 2024, Arcadyan's energy intensity reached 743.5 kWh per million in revenue, representing a 15.2% reduction compared to 2023. This exceeded the annual target of a 1% reduction in energy intensity, demonstrating Arcadyan's firm commitment and tangible progress in improving energy efficiency.

Arcadyan has implemented energy intensity tracking to continuously monitor energy and carbon performance per unit of operational output. This ensures that, even as the company expands its operations, it can steadily reduce carbon emissions per unit and advance in parallel toward both sustainable growth and climate responsibility.

Arcadyan Headquarters Smart Power Management Initiative

Since 2023, Arcadyan’s Hsinchu headquarters has partnered with an external energy technology service provider to implement an energy management project. The initiative focuses on identified energy hotspots, such as high-consumption air-conditioning systems including chillers and cooling towers. Through energy-use structure analysis and the introduction of automated monitoring systems, the project has enhanced transparency and visualization of energy consumption. Variable frequency drives (VFDs) and temperature monitoring interfaces were installed on the chillers to transmit real-time temperature data to the central controller, which automatically adjusts the motor operation accordingly. This has improved system responsiveness and efficiency, reduced energy waste, and ensured stable indoor temperatures. Additionally, the installation of VFDs and monitoring interfaces has extended equipment lifespan and lowered maintenance costs. Arcadyan will continue to leverage innovative technologies and effective power management to advance its sustainability objectives.。

Vietnam Manufacturing Center Energy Monitoring Control Room

In 2023, Arcadyan’s Vietnam Manufacturing Center established a real-time Energy Monitoring Control Room, supported by a 24/7 central monitoring system. The system enables energy consumption analysis, real-time alerts, and diagnostic functions to ensure transparency in electricity use and effective implementation of energy-saving measures. It promptly identifies abnormal consumption patterns and facilitates adjustments to optimize energy efficiency. As a result, the system saves approximately 360 MWh of electricity annually, equivalent to around 260 metric tons of carbon emissions. These efforts not only reduce energy costs but also minimize environmental impact, advancing Arcadyan’s goal of green production.

Water Resource Management

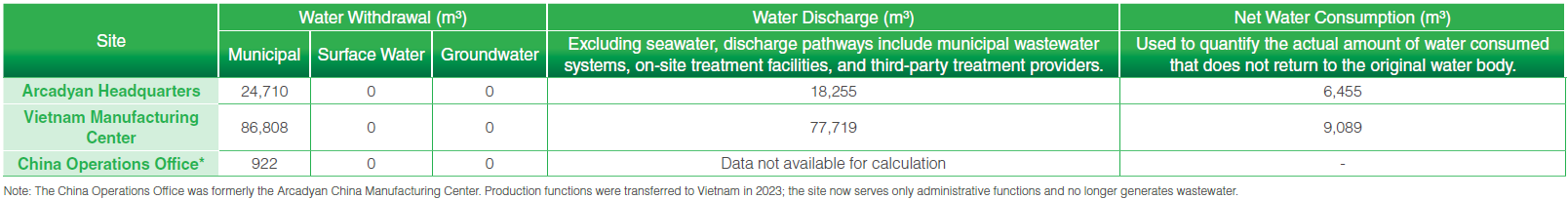

Arcadyan installs appropriate water treatment and management facilities based on the specific water usage patterns and wastewater characteristics at each operating site. These systems ensure that discharged water complies with regulatory standards while minimizing potential environmental impact. At headquarters, the kitchen is equipped with a grease separation system, effectively reducing the discharge of oily waste into the sewage system and the environment. All wastewater and discharge water across sites consistently meet or exceed local environmental standards. Ongoing water quality monitoring and risk management mechanisms are in place to further strengthen environmental protection efforts. Following the relocation of manufacturing capacity from China to Vietnam, the former China manufacturing center, now operating solely as the logistics and administrative office, no longer engages in production activities. Daily water consumption is limited to basic domestic use, resulting in a significant reduction in both water intake and discharge volumes, and thereby lowering environmental impact.

The Vietnam manufacturing center, which operates as an assembly-type facility, primarily uses water for domestic purposes. In 2024, approximately 77,719 cubic meters (m³) of wastewater were treated and reused through the onsite wastewater treatment system, achieving a 50% water recycling rate, effectively reducing reliance on municipal water supplies. Unrecycled wastewater is discharged into the municipal sewer system and processed at local wastewater treatment plants. Third-party testing is conducted annually to monitor water quality parameters including pH, chemical oxygen demand (COD), suspended solids (SS), ammonia nitrogen, total phosphorus, and total nitrogen. All test results complied with local discharge standards, with no instances of direct contamination to water bodies or soil. In 2024, no environmental violations, major spills, or lawsuits exceeding NT$2 million related to water discharge occurred at any Arcadyan site.

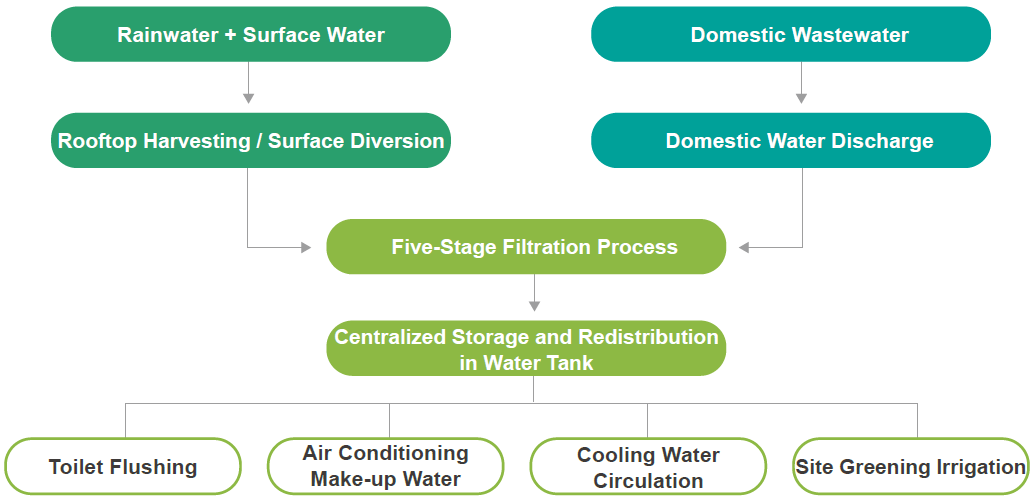

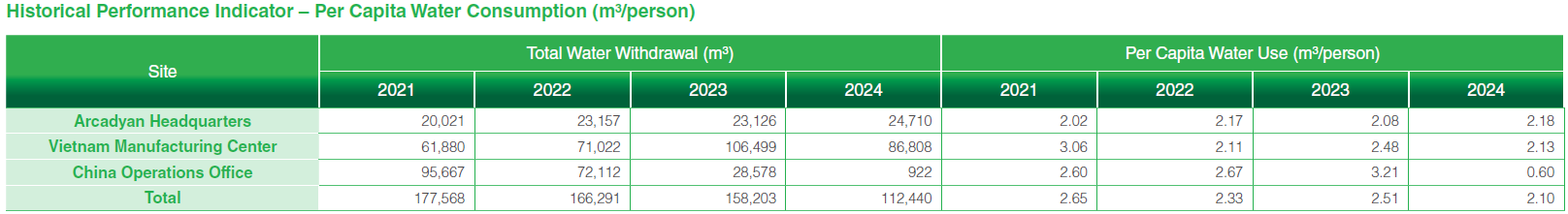

In 2024, Arcadyan Group's average monthly water consumption per capita was 2.1 cubic meters/person, representing a 16.3% decrease compared to 2023. This achievement surpassed the annual water conservation target of a 1% reduction, demonstrating the effectiveness and consistency of water-saving efforts. The primary contributor to this improvement was the full implementation of a domestic wastewater recycling system at the Vietnam Manufacturing Center in 2024, which significantly improved reclaimed water efficiency and reduced dependence on municipal water supply. This system recycles domestic wastewater through a multi-stage filtration process, enabling water reuse. The initiative not only reduces overall water costs but also enhances the resilience and flexibility of wastewater management at the site, reflecting Arcadyan's strong commitment to water sustainability and environmental responsibility in its operations.

Water Conservation and Recycling Measures

Arcadyan implements a variety of water conservation and recycling initiatives based on the function and water usage characteristics of each operating site. These efforts aim to improve overall water efficiency, reduce reliance on municipal water supplies, and strengthen the company's commitment to sustainable water resource management. The Arcadyan Headquarters, which serves as a research and development-focused office building, primarily consumes water for domestic purposes, with no use of process water. All wastewater is discharged into the municipal sewage system, causing no direct impact on local water bodies. To enhance water efficiency, the headquarters has adopted a rainwater harvesting system, automated irrigation equipment, and high-efficiency water-saving fixtures—maximizing the benefits of resource use through infrastructure upgrades.

Since its establishment in 2021, the Vietnam Manufacturing Center has been equipped with a rainwater harvesting system that collects rainwater and surface runoff through rooftop and ground catchment systems. After initial filtration, the water is reused for toilet flushing and landscape irrigation, effectively reducing the use of tap water. At the end of 2023, the site further implemented a domestic wastewater recycling system. Using a five-stage filtration process, the system treats and reuses both rainwater and domestic sewage collected in a central storage tank, and redistributes the water for various uses including toilet flushing, air conditioning makeup water, cooling circulation, and green area irrigation. In 2024, the rainwater and wastewater recycling systems together reclaimed 77,719 cubic meters of water, accounting for 50% of the site's total water usage. This significantly increased the proportion of recycled water and delivered substantial water-saving results. Arcadyan will continue to evaluate water usage patterns across its operations, gradually expand recycling system capacity, and optimize water management strategies to achieve more efficient and environmentally responsible water use.