Arcadyan actively assesses climate-related risks and opportunities to its operations and embeds green design principles throughout product development. Following the Product Life Cycle (PLC) approach, the company evaluates environmental impacts across all stages—from raw materials and manufacturing to usage and end-of-life—with a focus on reducing resource use and carbon emissions. Aligned with circular economy principles, Arcadyan applies Cradle to Cradle design to support a sustainable “manufacture–use–recycle” model. Starting from design, the company enhances resource efficiency, minimizes pollution and waste, and advances eco-friendly innovation. This approach reduces environmental impact while strengthening product sustainability and competitiveness.

At the design stage, Arcadyan aligns customer needs and product functions with energy efficiency and low-carbon performance, while complying with global standards such as the EU Eco-design Directive. Since 2006, all products have maintained 100% compliance with the EU WEEE Directive and other regional laws, with no violations of labeling or voluntary standards—demonstrating a strong commitment to environmental compliance.

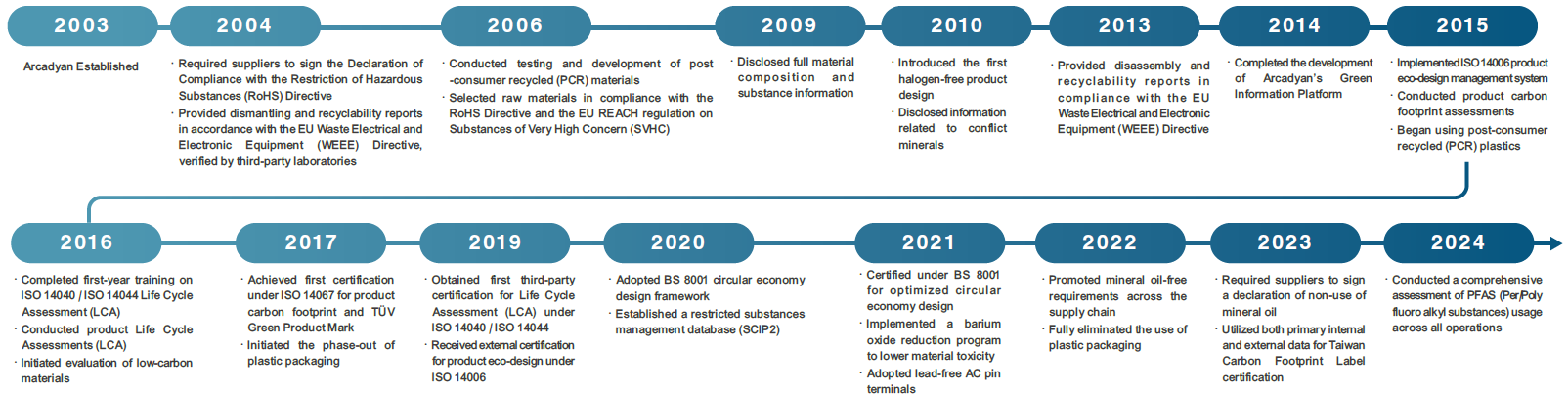

Arcadyan's Sustainable Product Development Journey

Arcadyan's product design is centered around four core principles: the use of low-toxicity materials, energy efficiency, ease of disassembly and refurbishment, and extended product lifespan. Since its founding, Arcadyan has continuously aligned with global sustainability trends, addressed stakeholder expectations and customer needs, and refined its environmentally friendly design capabilities. The company is committed to enhancing the sustainability performance of its product life cycle to achieve optimal eco-effectiveness.

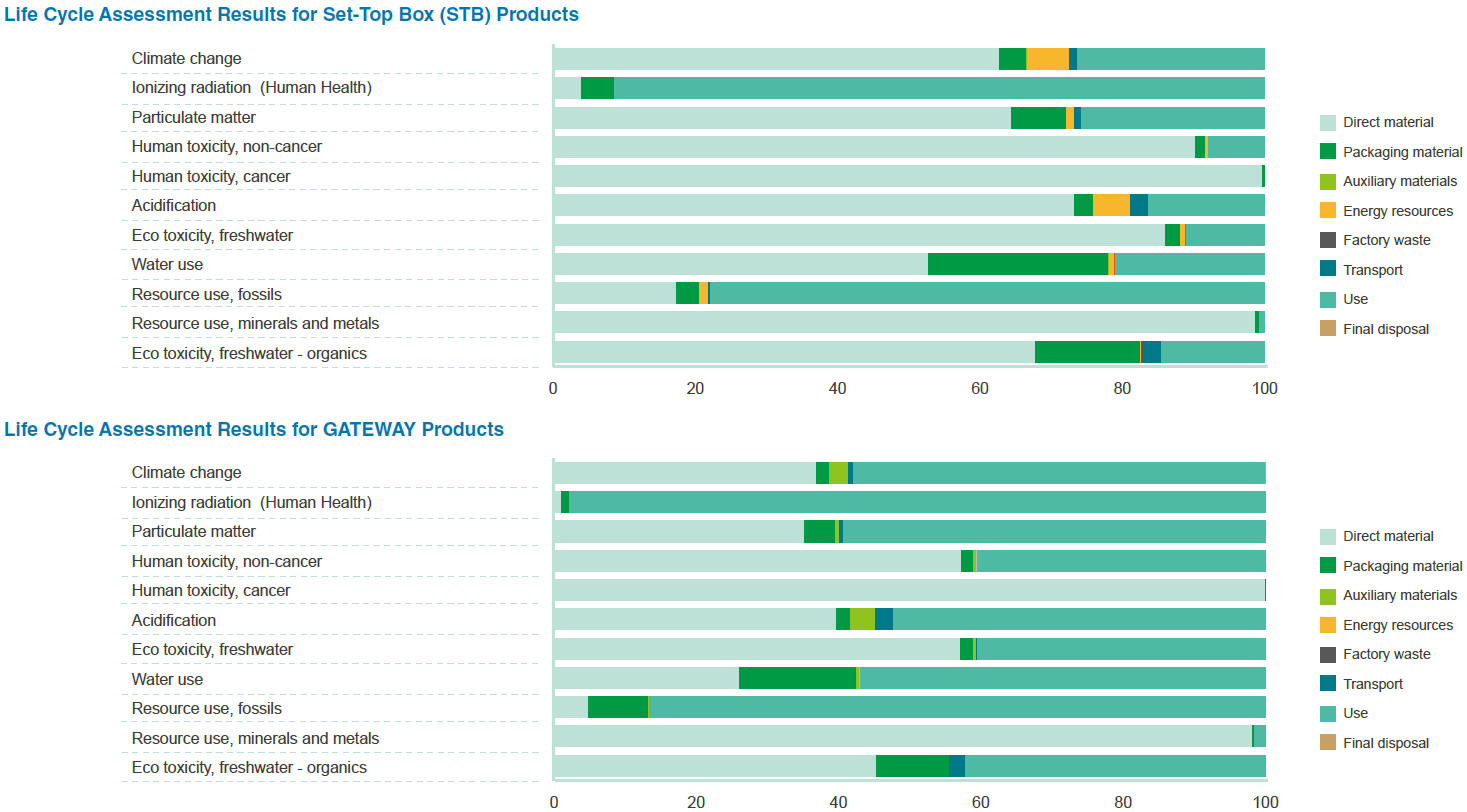

Product Life Cycle Assessment

Arcadyan conducts LCA in accordance with ISO 14040 and ISO 14044 standards, using specialized software to assess environmental impacts and carbon footprints. The assessment framework is aligned with the EU's Product Environmental Footprint (PEF) methodology and the Product Category Rules (PCR) for IT equipment, which define five key life cycle stages: raw material acquisition, manufacturing, distribution, use, and end-of-life treatment. Evaluations cover 27 environmental impact categories, including climate change, human toxicity, freshwater ecotoxicity, mineral resource depletion, and fossil resource depletion. In 2024, products undergoing LCA at the request of customers accounted for approximately 10% of total shipments— highlighting Arcadyan's commitment to transparency in environmental information and the advancement of sustainable product design.

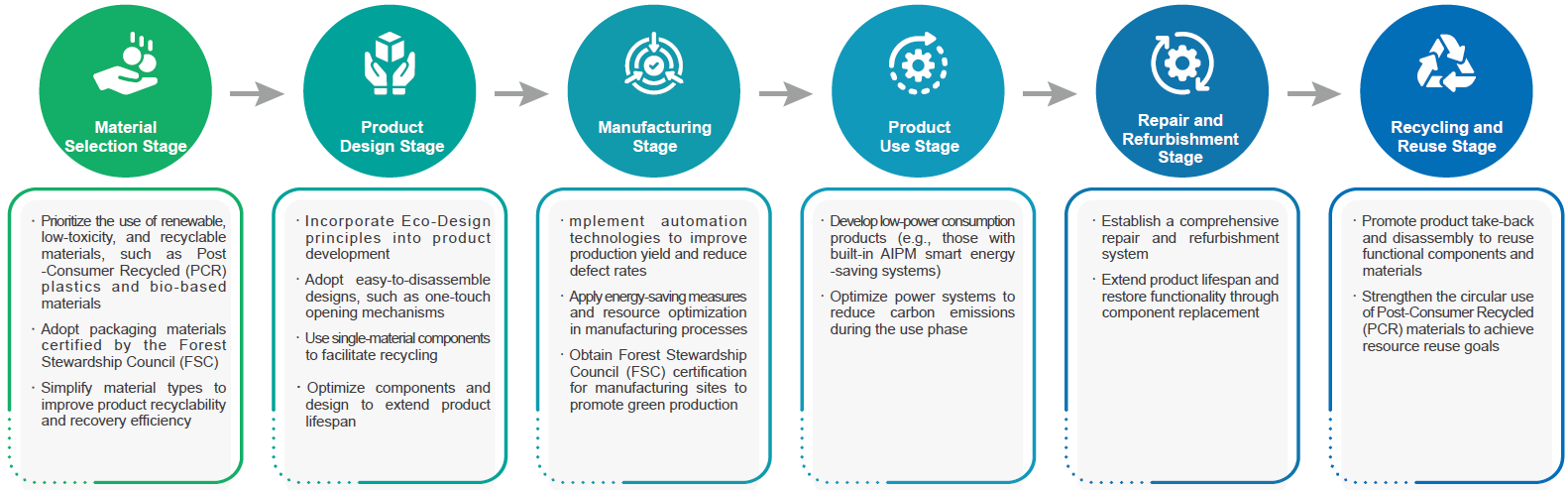

Arcadyan's Sustainability Strategy for Green Design and Circular Economy

In response to global challenges such as climate change and resource depletion, Arcadyan adopts Product Life Cycle Management (PLCM) as a core strategy. The company integrates environmental considerations into every stage of the “Cradle to Cradle” approach—including material selection, product design, manufacturing, usage, repair and refurbishment, and end-of-life recycling. Through this systematized and integrated sustainable design process, Arcadyan implements carbon reduction, energy efficiency, and resource circulation strategies to enhance product recyclability and environmental value.

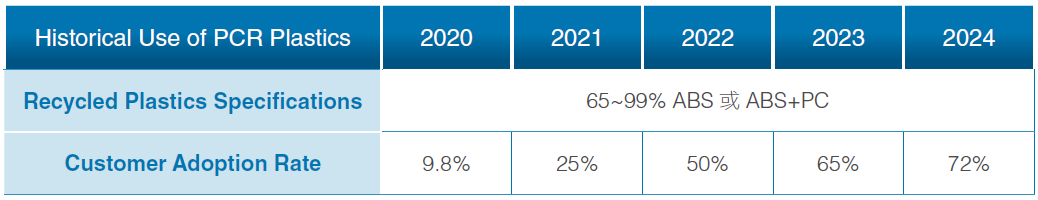

Use of Post-Consumer Recycled (PCR) Plastics

Arcadyan actively promotes the circular use of plastic materials by developing high-recyclability plastic compounds and increasing the proportion of recycled content in its products. Since 2015, Arcadyan has incorporated 65% to 99% post-consumer recycled (PCR) plastic into product plastic components. For materials such as ABS or ABS+PC, a clip-fit structure is used in place of traditional screw-fastening methods to reduce screw usage, improve structural strength, and facilitate recyclability. In 2024, approximately 72% of Arcadyan's shipped products included recycled plastics, achieving its target of exceeding 70%. This reflects Arcadyan's strong commitment to advancing material circularity. The company will continue to enhance the development and application of recycled materials, aiming to reach a 75% adoption rate in customer products by 2025, thereby deepening the implementation of circular economy practices.

Eco-Friendly Packaging Design

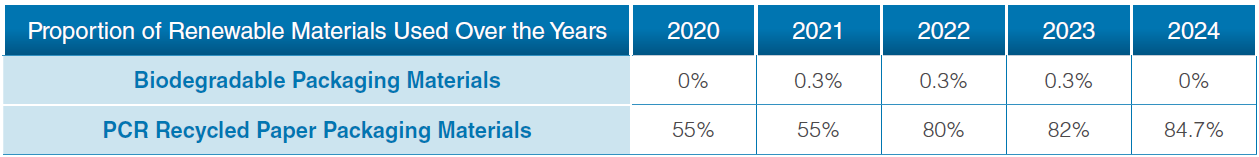

Arcadyan is committed to reducing the use of packaging materials by optimizing packaging structure to improve transportation efficiency and reduce carbon emissions. In material selection, the company prioritizes recycled paper and Forest Stewardship Council (FSC)-certified materials, and uses plant-based inks instead of traditional petroleum-based inks to reduce environmental impact. In 2024, over 84% of shipped products used recycled paper, and 80.6% were packaged with FSC-certified materials. Additionally, Arcadyan's Vietnam manufacturing site obtained FSC certification, further strengthening traceability and quality control of packaging sources.

Arcadyan also uses biodegradable materials such as industrial starch, plant fibers, and molded pulp foam for internal packaging components, enabling composability and natural degradation. However, in 2024, due to customer demands, these materials were replaced with more cost-effective and readily available paper-based alternatives. Going forward, Arcadyan will continue to monitor developments in sustainable materials and seek solutions that balance environmental and economic performance, supporting its circular economy and carbon reduction goals.

Material Simpli cation and Improved Recycling Ef ciency

To enhance product recyclability, Arcadyan simplifies material composition by prioritizing single-material designs and reducing the use of mixed materials. For packaging, product information is printed directly on the outer box to minimize paper usage. Accessory bundling has shifted from traditional plastic ties to paper-based alternatives to reduce environmental impact. The product foot pads are designed to be replaceable, improving repair and refurbishment convenience and extending product lifespan. Additionally, electronic directive icons and EU compliance markings are integrated directly into the product housing, streamlining the manufacturing process and facilitating recycling. These measures reflect Arcadyan's comprehensive implementation of sustainable design and its strong commitment to environmental responsibility.

Eco-Design of Products

Arcadyan was certified to ISO 14006 in 2018 and adopted a structured approach to ecodesign.

This includes life cycle data collection and carbon assessment through four steps: goal and scope definition, Life Cycle Inventory Analysis, impact assessment, and interpretation. This systematic method enables a comprehensive understanding of environmental impacts across all product stages, with environmental disclosure reports used as the basis for thirdparty verification. The ISO 14006 eco-design standard has been applied to the development of Arcadyan's router and set-top box (STB) product lines. For example, the latest generation of routers achieves a reduction of approximately 4 kgCO2e per unit—around 7% of the total product emissions—and has received TÜV Green Mark carbon footprint verification. For STBs, the carbon reduction is approximately 2 kgCO2e per unit, or 5% of total emissions, with verified carbon footprint certification also obtained. Arcadyan will continue to expand the application of restricted substance management for raw materials, deepen the development of low-carbon products, and actively advance its environmental sustainability goals.

Improving Printed Circuit Board (PCB) Utilization

Arcadyan has implemented a high-efficiency PCB design strategy by reducing the distance between components and board edges to just 1 mm, increasing material utilization to over 85%. This reduces raw material use, lowers carbon emissions, and cuts procurement costs. Although this design requires overcoming challenges such as fixture limitations and edge stress risks, it significantly improves resource efficiency. Preliminary estimates suggest a potential carbon reduction of about 0.03%, supporting Arcadyan's green manufacturing and carbon reduction goals.

Design for Easy Disassembly (One-Hand Opening Structure)

To meet customer needs for product refurbishment and recycling, Arcadyan has introduced a one-hand opening structure in product design to improve maintainability and repairability. The design replaces traditional screwfastening with a screwless snap-fit mechanism, enabling quick and damagefree disassembly using specialized tools.

This approach shortens disassembly and repair time while eliminating the need to sort screws during recycling. The product housing uses a single plastic material to simplify recycling and avoid contamination from mixed materials. In 2024, four product models adopted this design. Through structural and process optimization, Arcadyan demonstrates its strong commitment to circular economy principles and environmentally friendly, serviceable product design.

Arcadyan Intelligent Power Management (AIPM)

Arcadyan has independently developed the Arcadyan Intelligent Power Management (AIPM) system, which uses smart microcontrollers (MCUs) to precisely manage product operation modes. The system automatically detects load conditions and dynamically adjusts power states in real time. In 2024, approximately 2.2% of Arcadyan's key customer shipments adopted AIPM. Testing showed that AIPM can reduce overall product energy consumption by 20% to 30%, significantly improving energy efficiency and supporting the company's low-carbon transition goals.

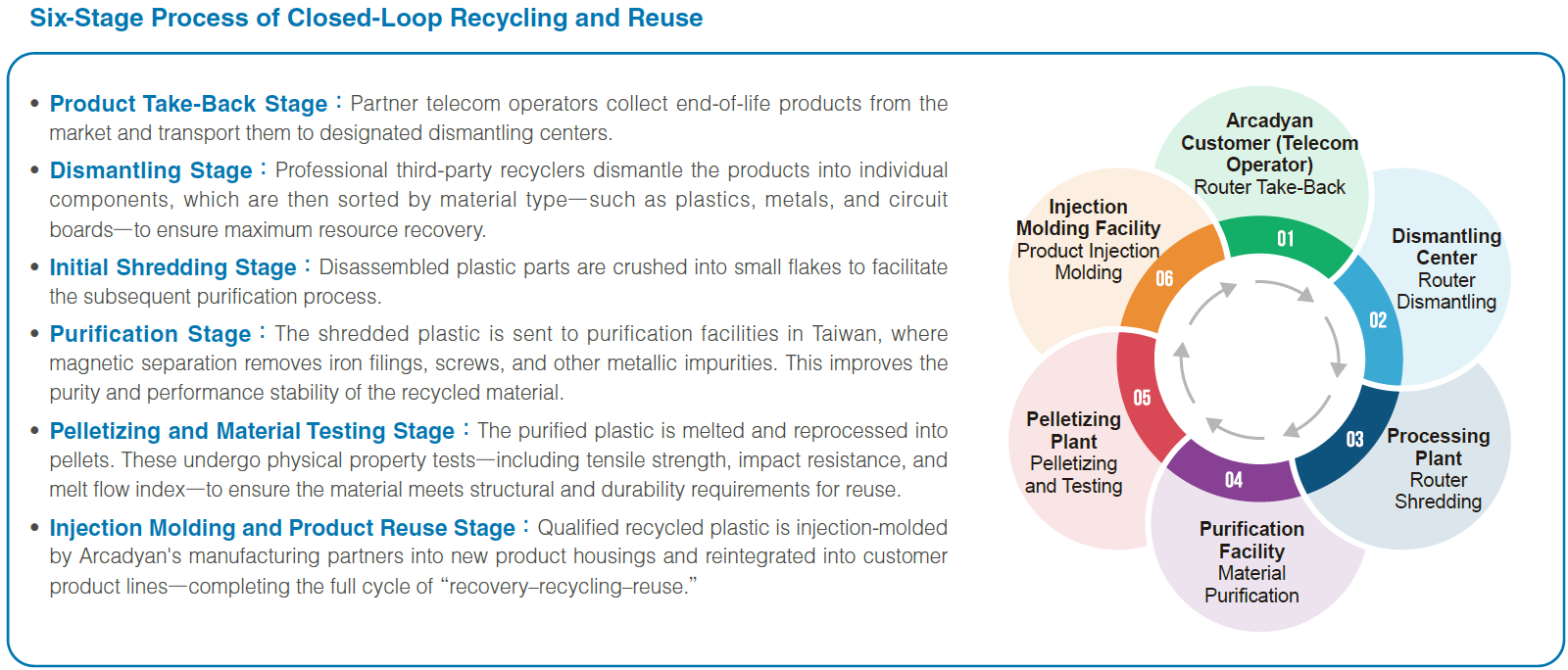

Circular Economy-Waste Recycling and Program

Arcadyan has established a closed-loop recycling model in collaboration with customers and supply chain partners. This model covers the full product life cycle—from market product recovery and material dismantling to purification and reintegration into new products. In 2024, Arcadyan recycled 3,909 kg of plastic, converting it into post-consumer recycled (PCR) material for reuse in manufacturing. This effort reduced approximately 28 metric tons of CO2e emissions and lowered reliance on virgin plastics.

Arcadyan will continue to strengthen partnerships with customers, recyclers, dismantlers, and suppliers to expand the types and applications of recovered materials. Through the “recover–reprocess–reuse” model, the company supports green supply chain transformation and demonstrates its commitment to circular resource use and greenhouse gas reduction.