Sustainable Procurement Policy

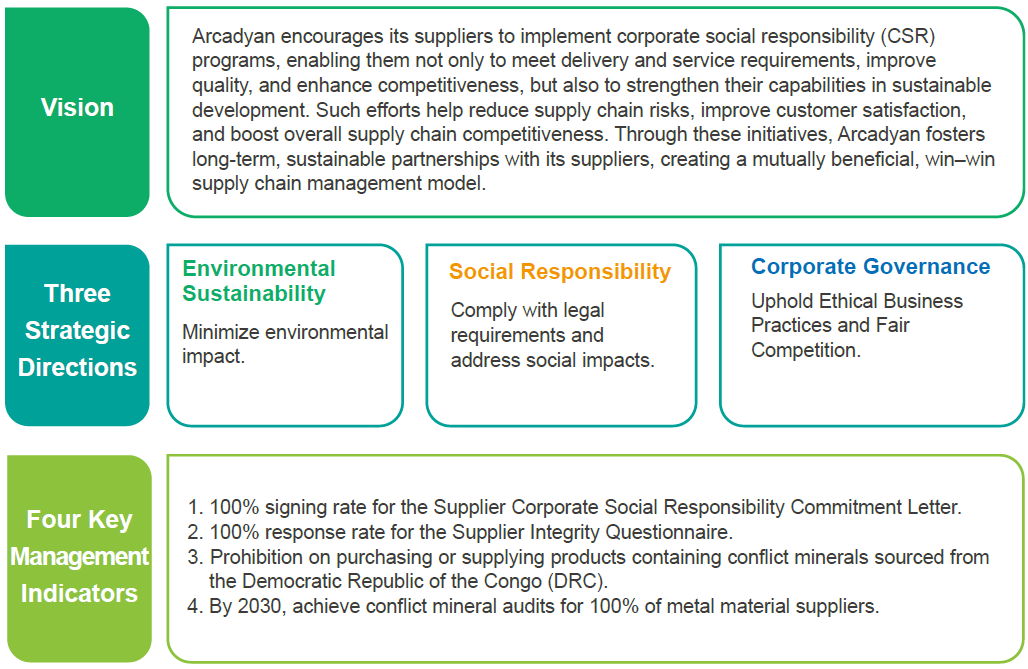

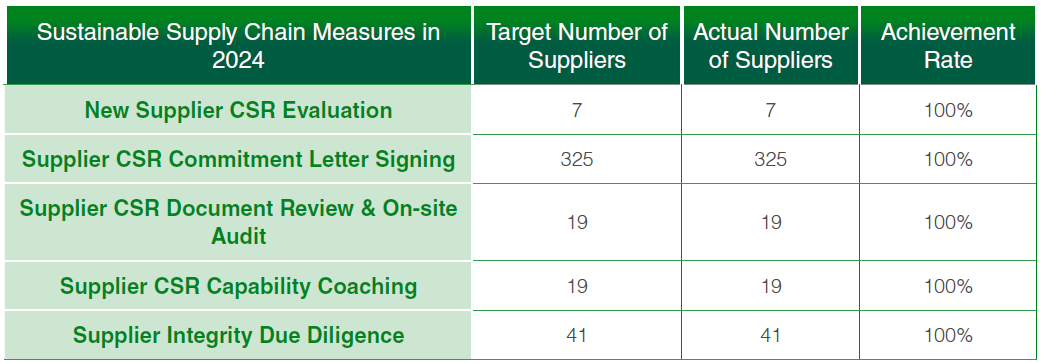

To support suppliers in adopting ESG practices and strengthening their sustainability resilience, Arcadyan has established the "Supplier Sustainability Investigation Standard", covering four key mechanisms: new supplier evaluation, ongoing supplier management, auditing, and coaching. "Arcadyan Sustainable Procurement Policy" serves as a key framework for implementing sustainable supply chain governance. In 2024, Arcadyan officially incorporated information security clauses into the updated "Arcadyan Supplier CSR commitment" covering seven key areas: organizational governance, labor rights, occupational health and safety, environmental protection, management systems, ethics standards, and grievance mechanisms. 325 suppliers have signed back on this commitment, achieving a 100% compliance rate. Arcadyan continues to require all suppliers to fully comply with domestic and international environmental and social laws and regulations, while strengthening the protection of confidential information to prevent potential data leakage in business transactions. These actions demonstrate Arcadyan's strong commitment to sustainable supply chain management and information security governance.

2024 Sustainable Supply Chain Achievements Summary

- Supplier Conference:

Facilitated knowledge sharing and discussions on emerging environmental and social issues facing the industry. Introduced the Green Product Management System platform and related compliance requirements, strengthening communication and engagement with suppliers. - Sustainable Procurement Training:

Conducted training sessions covering the ISO 20400 Sustainable Procurement Guidelines and common issues identified in RBA audits. A total of twenty-one procurement staff participated, accumulating forty-two training hours, achieving a 100% training completion rate. - Supplier CSR Commitment Signing:

Achieved a 100% return rate for the Supplier Corporate Social Responsibility Commitment Letter, which covers seven key management principles, promoting supplier compliance with environmental and social responsibility standards. - New Supplier Evaluation:

Completed assessments for twenty-one new suppliers, covering aspects such as labor rights, health and safety, environmental protection, corporate governance, business ethics, and grievance mechanisms. - Supplier Risk Assessment:

Conducted comprehensive evaluations based on product category, transaction status, and ESG performance. In 2024, no high-risk suppliers were identified; nineteen medium-risk suppliers were selected for on-site audits. - Supplier Audit:

In accordance with RBA standards, Arcadyan completed on-site audits for sixteen medium-risk suppliers and remote document reviews for three suppliers. Additionally, distributed integrity questionnaires to forty-one suppliers, achieving a 100% response rate with no findings of business ethics violations or inappropriate hospitality.

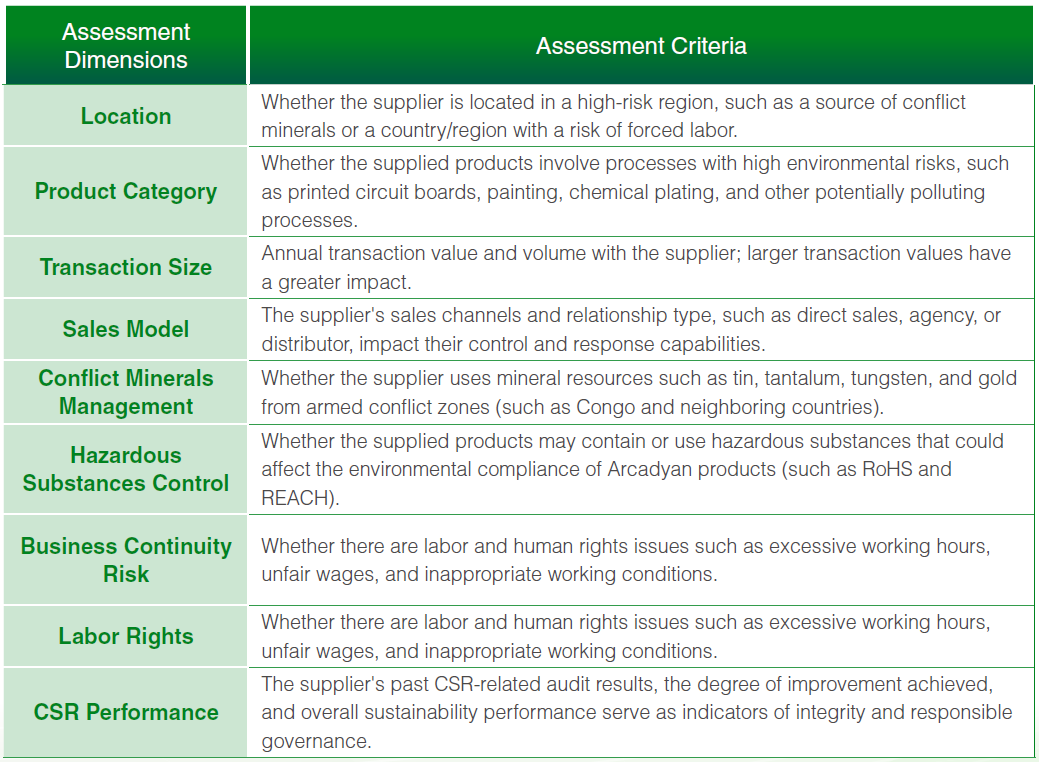

Supplier Sustainability Risk Assessment

Arcadyan developed a supplier sustainability risk assessment mechanism to enhance supply chain management efficiency and resilience through the identification of potential risks. The assessment covers nine key dimensions: location, product category, transaction size, sales model, conflict mineral management, hazardous substances control, business continuity risk, labor rights, and CSR performance. A comprehensive evaluation is conducted through questionnaires and data analysis. In 2024, the assessment results indicated no high-risk suppliers. For forty-one medium-risk suppliers, Arcadyan completed 100% of integrity due diligence investigations, ensuring integrity and responsible governance across the supply chain.

Supplier CSR Audits

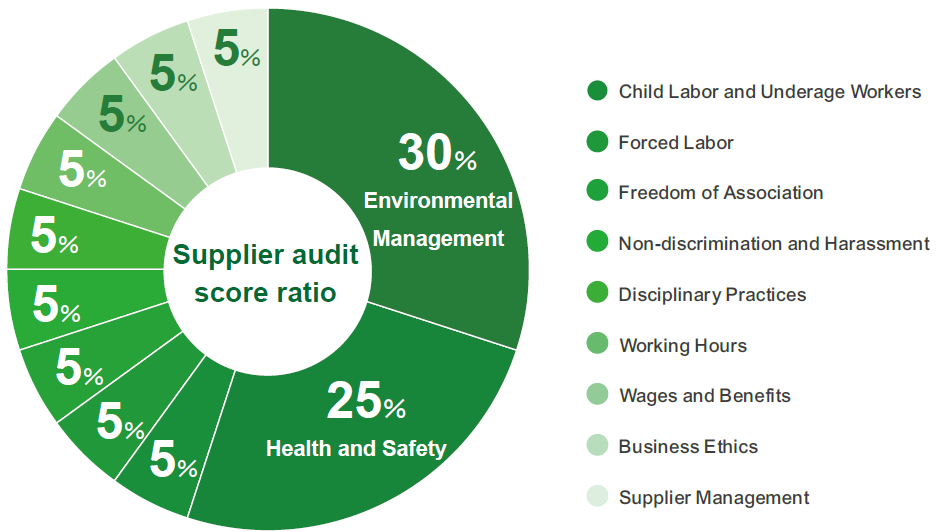

In alignment with the Responsible Business Alliance (RBA) Code of Conduct, Arcadyan developed a Supplier CSR Audit Checklist to conduct on-site reviews for suppliers identified as having potential high-risk factors. The audit covers eleven key dimensions, with "Environmental Management" and" Health and Safety" accounting for 55% of the total score, and the remaining nine dimensions comprising the other 45%. In 2024, Arcadyan selected nineteen key suppliers from the medium-risk list for on-site audits, completing sixteen onsite inspections and three document reviews, achieving a 100% completion rate. Additionally, in response to clients' requirements, Arcadyan conducted an on-site audit and improvement guidance for one Tier-2 supplier, further expanding the depth of sustainable supply chain management and enhancing accountability.

Since 2016, Arcadyan has actively participated in the Joint Alliance for CSR (JAC), working with global telecommunications operators to advance Corporate Social Responsibility (CSR) practices within the Information and Communications Technology (ICT) industry supply chain. In 2024, Arcadyan arranged six suppliers to participate in JAC audits. For suppliers that did not meet the required standards, Arcadyan provided immediate assistance in setting improvement targets and timelines, along with support resources, to continuously strengthen the effectiveness of sustainable supply chain management.

Supplier Coaching

Arcadyan continues to strengthen the sustainability capabilities of its suppliers by regularly following up and providing improvement guidance on non-conformities identified during Corporate Social Responsibility (CSR) audits. In 2024, Arcadyan guided nineteen suppliers to complete corrective actions for CSR-related deficiencies, with the three primary areas of improvement—Health and Safety, Environmental Management, and Working Hours & Overtime—accounting for approximately 70% of all findings. In the area of environmental management, Arcadyan established a professional green information platform to provide the latest updates on international environmental regulations and procedural requirements. This platform enables suppliers to stay informed about regulatory changes, monitor compliance status, and access real-time records of document submissions and updates, thereby enhancing overall supply chain compliance capability.

Arcadyan also actively participates in client-initiated Sustainable Development Programs (SDP), assisting suppliers in adopting the management standards of the Responsible Business Alliance (RBA) and the Joint Alliance for CSR (JAC). The program focuses on ten aspects of ESG, including strategy, management system, stakeholder engagement, resource management, environmental management, life cycle thinking, worker treatment, labor practices, human rights, and supplier development. This is a two-year project aimed at improving sustainability performance, during which Arcadyan supports suppliers in developing sustainability management programs. In 2024, two suppliers participated in this initiative and achieved Silver-level sustainability performance certification.

Recognition of Outstanding Suppliers

Arcadyan revised its Outstanding Supplier Selection Mechanism, with evaluation criteria covering suppliers' incoming material quality performance, number of customer complaints, effectiveness of corrective actions, and service coordination capability for the year. In addition, Corporate Social Responsibility (CSR) performance has been added as a scoring category to strengthen the overall sustainability performance of the supply chain. In procurement decisions, Arcadyan gives priority consideration to suppliers recognized as outstanding, to acknowledge their overall performance. For suppliers whose performance does not meet the standard, procurement allocation may be adjusted based on their improvement progress, and such performance serves as a reference in the supplier phase-out mechanism.

To commend partners that have excelled in environmental and social performance, Arcadyan awarded 15 outstanding suppliers, encouraging the supply chain to collectively enhance CSR performance. Arcadyan continues to focus on innovative products and technologies, integrating upstream and downstream resources to provide clients with comprehensive sustainable solutions, while actively taking responsibility for Arcadyan's economic, social, and environmental impacts to foster a positive cycle of industrial and environmental sustainability.

Go Green with Arcadyan Carbon Reduction Project

Program Background

In response to growing international policy trends and the increasing attention from brand clients on carbon reduction and supply chain sustainability performance, Arcadyan actively addresses the challenges of carbon footprint management, energy efficiency improvement, and net-zero commitments. In 2022, Arcadyan joined the Science Based Targets initiative (SBTi) and officially launched its long-term carbon reduction roadmap. Arcadyan has committed to reduce Scope 1 and 2 greenhouse gas emissions by 50% and Scope 3 emissions by 66% compared to the base year by 2030, reduce Scope 1 and 2 emissions by 90% in 2024, and achieve net-zero emissions across all scopes by 2050.

To fulfill these commitments, Arcadyan launched the "Go Green with Arcadyan" Supply Chain Carbon Reduction Project in October 2023. In the first phase, 14 high carbon emission suppliers were invited to participate, covering six major categories of key components: adapters, cables, casings, connectors, heat sinks, and printed circuit boards. The program promotes supplier carbon inventory, target setting, and carbon reduction actions to enhance climate resilience and international competitiveness.

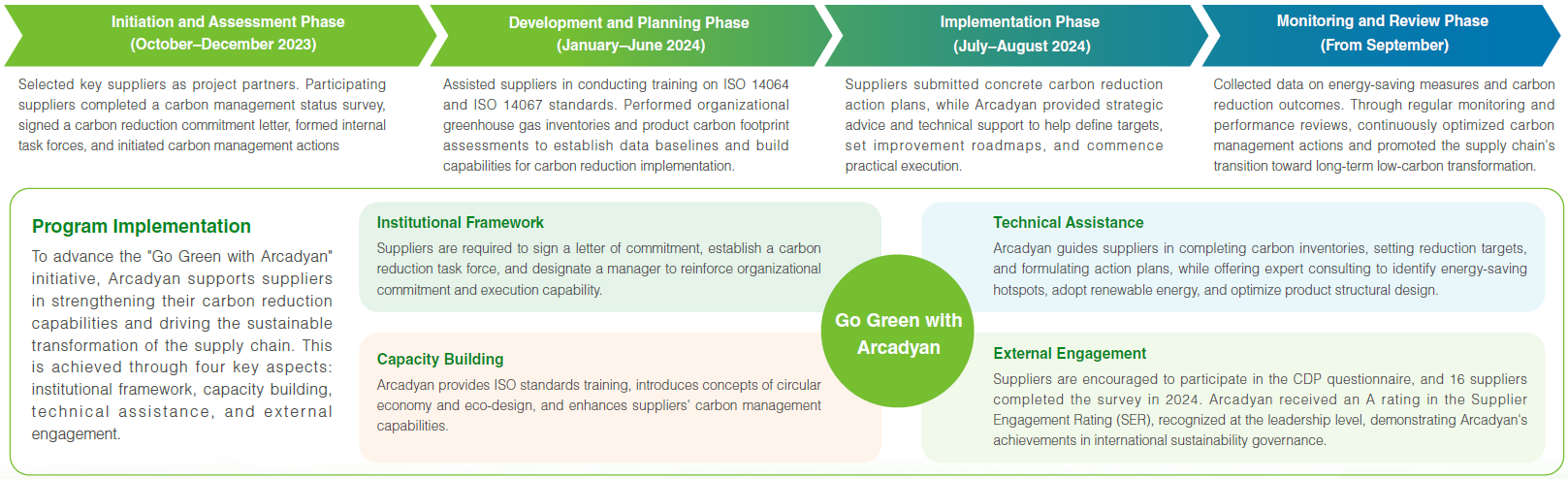

Program Timeline

The "Go Green with Arcadyan" project began in October 2023 and run for one and a half years. Based on the progress of supply chain carbon management, the program is implemented in four phases:

Project Results

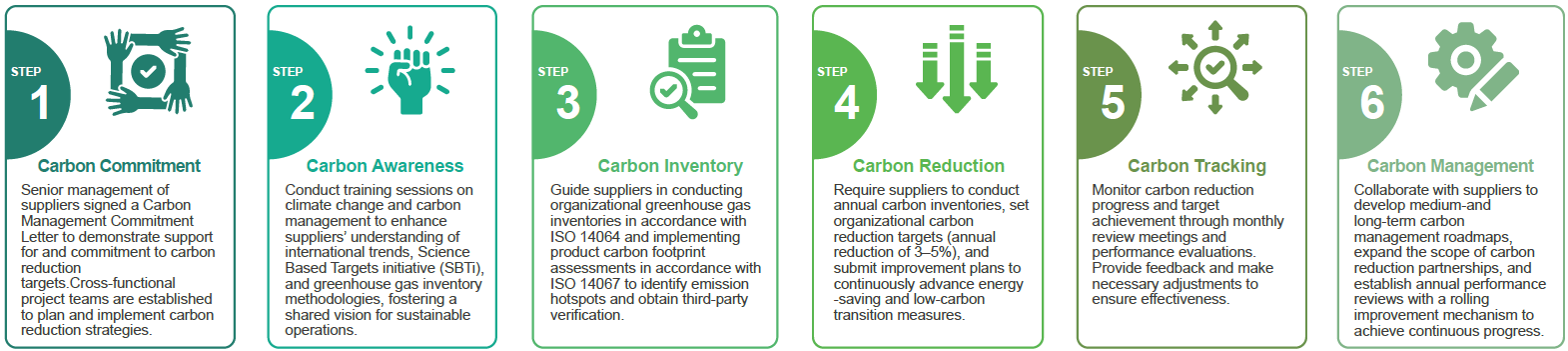

Through the "Go Green with Arcadyan" initiative, Arcadyan has helped suppliers establish carbon management capabilities and practical implementation mechanisms, enhancing their awareness of and responsiveness to climate risks and resource management issues. The results are as follows:

- Organizational Level (Scope 1+2):

Ten suppliers completed ISO 14064 organizational greenhouse gas inventory verification. Six suppliers installed solar power generation systems, and four suppliers purchased renewable energy certificates. Energy-saving measures included replacing high-energyconsuming equipment, introducing intelligent energy management systems, and implementing waste heat recovery systems. These actions achieved a total carbon reduction of 95,302 metric tons CO2e. - Product Level (Scope 3):

Five suppliers obtained ISO 14067 certification, promoting product miniaturization, lightweight design, and the use of post-consumer recycled (PCR) materials. Packaging improvements included switching to kraft paper cards, reducing packaging material usage, adopting reusable plastic crates and cardboard box recycling, and optimizing logistics routes and loading efficiency to reduce transport-related carbon emissions. These measures resulted in a reduction of 11,106 metric tons CO2e. - Strategic Alignment:

Two suppliers joined the Science Based Targets initiative (SBTi), aligning with international trends such as the European Union Carbon Border Adjustment Mechanism (CBAM), sustainable procurement, and circular design.

Local Procurement

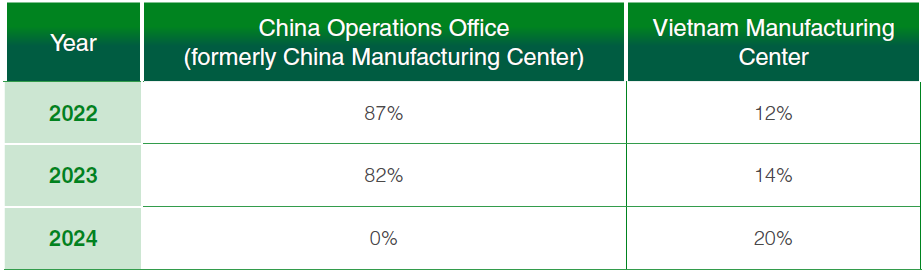

Arcadyan positions its Vietnam manufacturing center as a key production base and has actively promoted a local procurement strategy over the years to enhance production and supply efficiency and expand economies of scale. The major components covered include power supply units, electronic parts, electromechanical parts (such as printed circuit boards), and mechanical parts, with primary supply sources from Taiwan, China, and Vietnam. As product applications have expanded and clients demand has increased, many Taiwan-based suppliers have not only expanded their existing plants but also established manufacturing facilities in China and Vietnam to provide localized support for production needs. To reduce energy consumption and carbon emissions from long-distance transportation of raw materials and products, Arcadyan has optimized packaging design, improved material space utilization, and adopted recyclable packaging while actively supporting local procurement to reduce transportation costs and environmental impacts.

To balance operational continuity with greenhouse gas emissions management from raw material transportation, Arcadyan implements a systematic procurement management process to continuously develop local suppliers and gradually increase the proportion of local procurement. However, in 2024, following the transformation of the China manufacturing center into an operations Office with no physical manufacturing operations, the local procurement ratio for the year was 0%. Arcadyan will continue to monitor supplier expansion and relocation progress, gradually increasing the proportion of local procurement to diversify and localize its supply chain. This approach aims to strengthen supply chain resilience, enhance manufacturing efficiency, and effectively reduce the carbon footprint from raw material transportation, thereby advancing the sustainable objectives of a green supply chain.

Responsible Minerals Management

To fulfill its corporate social responsibility and in response to global concerns over human rights and environmental sustainability, Arcadyan has actively supported the "Conflict-Free Minerals" initiative since 2010, promoting the investigation and management of material sources across its supply chain. Recognizing the issues of armed conflict, child labor exploitation, and environmental destruction in the Democratic Republic of the Congo (DRC) and its surrounding regions, Arcadyan has established the "Arcadyan Sustainable Procurement Policy", which requires all supply chain metals to be legally sourced, compliant, and responsibly obtained, in accordance with the standards of the Responsible Minerals Initiative (RMI).

Arcadyan Con ict Minerals Policy

- Prohibit conflict minerals from the Democratic Republic of Congo (DRC) and surrounding regions.

- Suppliers are required to sign the "Non-use Conflict Minerals Declaration" to comply with relevant environmental and social responsibility regulations.

- Suppliers are required to disclose the source of the metals used, such as tantalum (Ta), tin (Sn), tungsten (W) (called 3T), cobalt (Co) and gold (Au), and fill in Conflict Minerals Reporting Template (CMRT).

- Taking the same requirements to manage the upstream supply chain, metal suppliers in related parts and components should investigate the refinery site before purchasing.

Management Mechanism and Implementation Process

Following the "Responsible Minerals Initiative" (RMI) standards, Arcadyan incorporates the prohibition of conflict minerals into its "Sustainable Procurement Policy". Arcadyan clearly stipulates that suppliers must sign "Arcadyan Supplier CSR commitment", pledging not to directly or indirectly procure conflict minerals from Democratic Republic of Congo (DRC) or surrounding regions. Suppliers must also ensure that their smelters/ refiners comply with the Responsible Minerals Assurance Process (RMAP) standards. All suppliers are required to submit the Conflict Minerals Reporting Template (CMRT) to track and manage the sources of gold (Au), tantalum (Ta), tungsten (W), tin (Sn), and cobalt (Co). In 2024, Arcadyan collected 518 CMRT reports with a 100% submission rate. The results confirmed that no conflict minerals were used within the supply chain.

To strengthen management effectiveness, Arcadyan Green Product Team regularly conducts conflict mineral analysis on key products, disassembling them to the smallest components and verifying the sources of contained metals for potential high-risk origins. Findings are documented in the Supplier Conflict Minerals Survey System, where the Green Product Department reviews supplier reports and supports documentation to ensure transparency and compliance. Since implementing responsible minerals management, Arcadyan has never experienced incidents of product returns, customer complaints, or reputational risks arising from noncompliance.

Furthermore, all suppliers are subject to regular assessments covering incoming material quality, customer complaint handling, and environmental and social responsibility performance (including conflict minerals and hazardous substances). Evaluation results serve as a basis for procurement strategy—suppliers with excellent performance are given procurement priority, while underperforming suppliers are considered for removal from the Qualified Vendor List (QVL) to ensure supply chain compliance and sustainability.

Responsible Minerals Training

Arcadyan conducts annual internal awareness training and organizes online briefings for suppliers, covering topics such as Arcadyan's Conflict Minerals Policy, key points in completing the Conflict Minerals Reporting Template (CMRT), and updates on international regulatory developments. Additionally, Arcadyan provides case-by-case coaching for suppliers to help them understand smelter certification processes and compliance requirements, thereby strengthening the overall responsible sourcing capabilities of the supply chain.

Reporting Channels and Traceability Mechanism

To ensure transparency and integrity within the supply chain, Arcadyan has established a dedicated reporting email (ethics@arcadyan.com) for suppliers, employees, and stakeholders to anonymously raise concerns regarding conflict minerals, high-risk mining areas, or human rights violations. If preliminary verification confirms the validity of a report, Arcadyan will immediately cease procurement, require the supplier to provide an explanation and corrective measures, and continue to track the progress of implementation to ensure resolution.